12Inch 13 Slot Y12-R0 Wafer Frame Cassette (10mm Slot Pitch)

Product Name: 12Inch 13 Slot Y12-R0 Wafer Frame Cassette (10mm Slot Pitch)

Number: DSF24Y12-000-R0

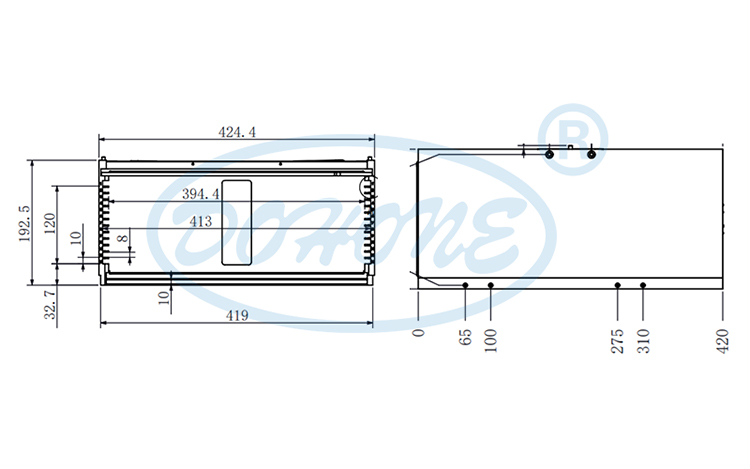

Size: 424.4(L)×420(W)×192.5(H)mm

Material: Aluminum alloy 6063(AL6063)

Number of slots: 13slots

Slot Pitch: 10 mm

Initial slot position: 32.7 mm

Product Process: CNC precision machining

Surface treatment: Anodization

Product Description

In semiconductor production facilities, equipment compatibility directly impacts the smoothness of the production process and cost control. From the initial design stage, the DOHONE 12-Inch 13 Slot Y12-R0 Wafer Frame Cassette has been developed with "compatibility with industry mainstream standards" as its core objective, strictly adhering to the technical parameters of mainstream semiconductor dicing equipment. Whether it is dicing equipment from internationally renowned brands like DISCO and ADT, or similar models from domestic mainstream manufacturers, this cassette achieves seamless compatibility in terms of dimensional specifications, slot spacing, and interface design. When enterprises introduce this product, they can directly deploy it into the production line without complex parameter adjustments or structural modifications to existing equipment. This not only significantly reduces the time costs and technical risks associated with equipment debugging but also meets the unified standardization requirements of multi-equipment production lines. It facilitates efficient integration within the production process and is particularly suitable for coordinated equipment operations in large-scale mass production scenarios.

If high-quality base materials form the product's "skeleton," then precision machining technology is the key that imbues the product with its "soul." The DOHONE 12-Inch 13 Slot Y12-R0 Wafer Frame Cassette is assembled and formed using CNC precision machining technology. Through multi-axis linkage machining systems and micron-level precision control systems, the product's verticality and flatness are maintained at industry-leading levels. In terms of verticality, the perpendicularity error between the cassette slots and the frame body is strictly controlled within 0.1mm. This level of precision ensures that when wafers are placed into the slots, they achieve accurate alignment with the slot walls, completely avoiding wafer misalignment caused by tilting, and ensuring that each wafer remains in its preset precise position during handling. As for flatness, the flatness error of the frame surface and slot bottoms does not exceed 0.2mm. Such a minute error range allows the wafers to achieve close contact with the cassette surface, effectively preventing wafer damage caused by uneven local stress. This provides a stable and reliable storage and transport carrier for subsequent processing steps such as dicing and inspection.

Q&A

Are you a factory or a trading company?

We are a factory.

How many staffs do you have in your factory?

Our company has nearly 70 staffs.

How many years have your company made this kind of equipment?

Our company has been serving the semiconductor industry for over 20 years, with extensive expertise in design and manufacturing.

What kinds of information do you need for a quote?

In order to quote for you earlier, please provide us with the following information together with your inquiry.

1.Product Model or Pictures

2.Material requirement(AL6063,AL6061,AL7075)

3.Surface treatment(Anodized,Hard Anodized,plating,sandblasting,brushing,etc)

4.Quantity(per order/per month/annual)

5. Any special demands or requirements, such as packing, delivery, labels, etc.

6.when do you expect to need the product?

What is your MOQ?

Standard products are available in stock with no minimum order quantity (MOQ) restrictions.