12Inch 13 Slot M12-R11 Wafer Frame Cassette (10mm Slot Pitch)

Product Name: 12Inch 13 Slot M12-R11 Wafer Frame Cassette (10mm Slot Pitch)

Number: DSF20M12-000-R11

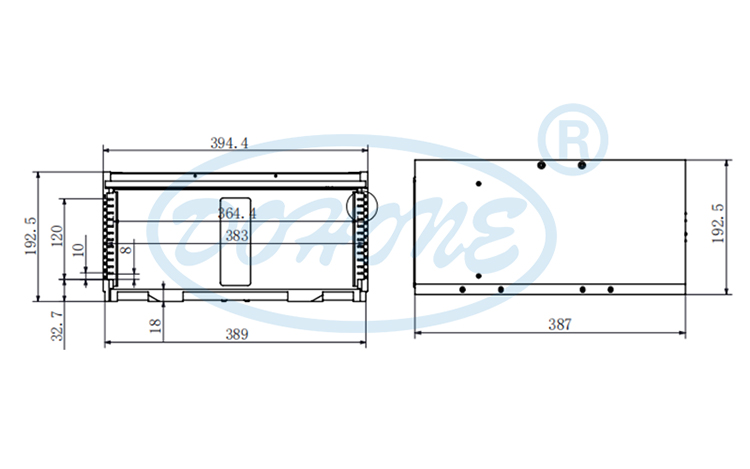

Size: 394.4(L)×387(W)×192.5(H)mm

Material: Aluminum alloy 6063(AL6063)

Number of slots: 13slots

Slot Pitch: 10 mm

Initial slot position: 32.7 mm

Product Process: CNC precision machining

Surface treatment: Hard Anodizing

Product Description

The DOHONE 12-Inch Wafer Frame Cassette utilizes an industry-leading hard anodizing process in the surface treatment stage. By precisely controlling the oxidation time and temperature, a dense and hard oxide film is formed on the product surface. This oxide film not only significantly enhances the hardness and scratch resistance of the cassette surface but also effectively blocks external moisture, dust, and other contaminants. This prevents surface corrosion or abrasion at the source, providing a stable and reliable foundation for subsequent wafer handling and processing.

Core Performance: Dual "No-Shedding" Protection for Processing Quality

Repeated Use Without Shedding Particles or Dust: Thanks to the excellent stability of the hard anodizing treatment, the cassette surface does not generate debris or leave residual powder during long-term, high-frequency wafer loading/unloading and transportation. This characteristic completely eliminates wafer surface contamination caused by the cassette itself, preventing defects such as scratches and breakage during the processing.

Ensures Wafer Dicing Process Quality: The particle-free and dust-free condition maintains a clean environment for the wafer throughout the dicing process, ensuring cutting precision and final product yield. Whether for large-scale mass production or high-precision custom processing, it helps reduce rework or scrap caused by carrier issues, thereby improving overall production efficiency.

Q&A

Are you a factory or a trading company?

We are a factory.

How many staffs do you have in your factory?

Our company has nearly 70 staffs.

How many years have your company made this kind of equipment?

Our company has been serving the semiconductor industry for over 20 years, with extensive expertise in design and manufacturing.

What kinds of information do you need for a quote?

In order to quote for you earlier, please provide us with the following information together with your inquiry.

1.Product Model or Pictures

2.Material requirement(AL6063,AL6061,AL7075)

3.Surface treatment(Anodized,Hard Anodized,plating,sandblasting,brushing,etc)

4.Quantity(per order/per month/annual)

5. Any special demands or requirements, such as packing, delivery, labels, etc.

6.when do you expect to need the product?

What is your MOQ?

Standard products are available in stock with no minimum order quantity (MOQ) restrictions.