6 inch 25 Slot B06-R0 Wafer Frame Cassette (4.75mm Slot Pitch)

Product Name: 6 inch 25 Slot B06 Wafer Frame Cassette (4.75mm Slot Pitch)

Number: DSF20B06-000-R0

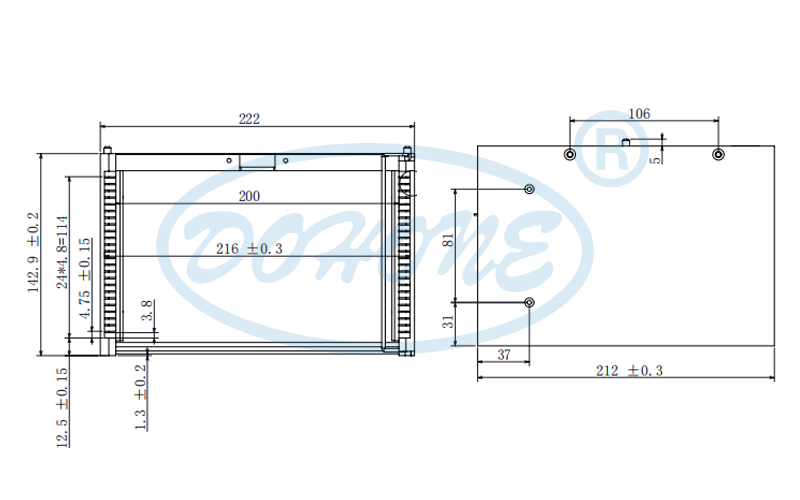

Size: 212(L)×222(W)×142.9(H)mm

Material: aluminum alloy 6063(AL6063)

Number of slots: 25 slots

Slot Pitch: 4.75 mm

Initial slot position: 12.5 mm

Product Process: CNC precision machining

Surface treatment: Anodization

Product Description

DOHONE leverages decades of technical expertise and market-driven insights to engineer the purpose-built 150mm Wafer Cassette. This cassette is precision-engineered to fulfill a critical role in semiconductor manufacturing: enabling high-throughput, precision-guided singulation of 150mm wafers into individual chips during the dicing process, thereby reinforcing process reliability at this pivotal production stage.

Tailored for small-to-medium semiconductor manufacturers, the 150mm Wafer Cassette addresses unique operational needs through advanced fabrication techniques. While their production volumes do not yet require large-capacity handling systems, these enterprises maintain uncompromising standards for product quality and throughput efficiency. DOHONE's solution bridges this gap with its optimized footprint, contamination-resistant architecture, and production-proven durability – delivering right-sized performance that integrates seamlessly into scaled manufacturing workflows. By balancing intelligent design with rigorous quality control, this cassette has become an operational linchpin for manufacturers seeking to maximize ROI without compromising precision in wafer processing operations.

DOHONE leverages decades of technical expertise and market-driven insights to engineer the purpose-built 150mm Wafer Cassette. This cassette is precision-engineered to fulfill a critical role in semiconductor manufacturing: enabling high-throughput, precision-guided singulation of 150mm wafers into individual chips during the dicing process, thereby reinforcing process reliability at this pivotal production stage.

Tailored for small-to-medium semiconductor manufacturers, the 150mm Wafer Cassette addresses unique operational needs through advanced fabrication techniques. While their production volumes do not yet require large-capacity handling systems, these enterprises maintain uncompromising standards for product quality and throughput efficiency. DOHONE's solution bridges this gap with its optimized footprint, contamination-resistant architecture, and production-proven durability – delivering right-sized performance that integrates seamlessly into scaled manufacturing workflows. By balancing intelligent design with rigorous quality control, this cassette has become an operational linchpin for manufacturers seeking to maximize ROI without compromising precision in wafer processing operations.

Certification qualifications

In today's highly competitive field of technology manufacturing, DOHONE has successfully won the ISO9001 quality management system certification with its outstanding technical R&D capabilities and strict quality control system. This certification is not only an authoritative recognition of the company's overall management level meeting international standards, but also a solid guarantee for the company to continuously deliver high-quality products and services to customers.

It is particularly worth mentioning that the wafer basket independently developed by the company, as a key instrument in the semiconductor production process, has condensed the wisdom of countless scientific researchers and has independent design patents. From the initial creative concept, to repeated simulation tests, to the final finalization of finished products, every link is striving for excellence, just to ensure that the wafer basket can help chip manufacturing companies improve production efficiency and reduce defective rates in a complex semiconductor manufacturing environment, injecting new impetus into the development of the global semiconductor industry with excellent stability and precise compatibility.

In the selection of product raw materials, DOHONE always adheres to the principles of high quality and environmental protection. All products are refined from high-quality materials certified by SGS. As a world-leading inspection, appraisal, testing and certification agency, SGS has strict certification standards, covering multi-dimensional testing such as physical properties and chemical stability, providing a reliable endorsement for the basic quality of products. At the same time, the company's products have also successfully passed the ROHS certification, which means that the product fully complies with EU standards in the control of harmful substances, guarantees the environmentally friendly attributes of the product from the source, enables it to travel smoothly in the international market, meets the strict requirements of international semiconductor companies for process technology, and helps customers seize the initiative in the global green technology wave. Whether facing the massive demand for high-performance chips in emerging fields such as 5G communications and artificial intelligence, or to cope with the challenges brought by the upgrading of the traditional electronics industry, DOHONE will take high-quality products as the cornerstone and work with partners to jointly explore the unlimited future of the semiconductor industry.

Custom Services

Founded in 2003, DOHONE specializes in semiconductor chip handling and storage solutions, having delivered 3,000+ customized product solutions to industry clients, all highly favored for their precision. We are confident in our ability to assist you. Simply provide your design specifications or samples, and we will deliver a tailored solution that meets your exact needs.

Delivery Lead Time for Wafer Cassettes

For standard 6-inch/8-inch/12-inch wafer cassettes (quantities up to 50 units), we generally require 5-7 business days for delivery. For larger quantities or non-standard/custom specifications, the delivery schedule will be mutually agreed upon and explicitly specified in the contract.

Q&A

Are you a factory or a trading company?

We are a factory.

How many staffs do you have in your factory?

Our company has nearly 70 staffs.

How many years have your company made this kind of equipment?

Our company has been serving the semiconductor industry for over 20 years, with extensive expertise in design and manufacturing.

What shall we do if we do not have drawings?

Please send your sample to our factory, then we can copy or provide you with better solutions, please send us pictures or drafts with dimensions(Thickness, Length, Height, and Width), CAD or 3D file will be made for you if you placed the order.

What kinds of information do you need for a quote?

In order to quote for you earlier, please provide us with the following information together with your inquiry.

1.Detailed drawings(STEP,CAD,SOLID Works,DXF,PDF)

2.Material requirement(AL6061,AL7075,SUS420J2,SUS304)

3.Surface treatment(Anodized,Hard Anodized,plating,sandblasting,brushing,etc)

4.Quantity(per order/per month/annual)

5. Any special demands or requirements, such as packing, delivery, labels, etc.

6.when do you expect to need the product?

What is your MOQ?

For custom products, the minimum order quantity (MOQ) can only be determined after confirming the product requirements.